MetalTec TC was developed by NASA in the United States after several years of research in the early 2000’s.

MetalTec TC was developed by NASA in the United States after several years of research in the early 2000’s.

One of its most remarkable characteristics is that it can withstand temperatures up to 260 ° C. with a thin layer of paint.

This makes MetalTec TC the most advanced product in its field, as it can withstand higher temperatures than any other TIC over long periods of time.

MetalTec TC product is an insulating ceramic coating, widely acceptec as the best thermal insulation coating today on the market.

It has been used in many different industrial installations all over the world, such as oil & gas, mining, food processing plants, shipping, etc.. Those various applications, which vary from one customer to another, demonstrate all the benefits and adaptability of the MetalTec TC.

Safety and personnel protection are major reasons for using MetalTec TC.

Safety and personnel protection are major reasons for using MetalTec TC.

MetalTec TC lowers the contact temperature of steam pipes, boilers and hot product tanks at the factory.

MetalTec TC lowers the contact temperature of steam pipes, boilers and hot product tanks at the factory.

Applying MetalTec TC to cold or frosted pipes minimizes or eliminates condensation,

which is a major cause of corrosion.The application of MetalTec TC outside hot air ducts (collectors and dust filters)

minimizes or eliminates condensation and agglomeration in the system.

Applying MetalTec TC to cold or frosted pipes minimizes or eliminates condensation,

which is a major cause of corrosion.The application of MetalTec TC outside hot air ducts (collectors and dust filters)

minimizes or eliminates condensation and agglomeration in the system. Perfect for PP. No more burn

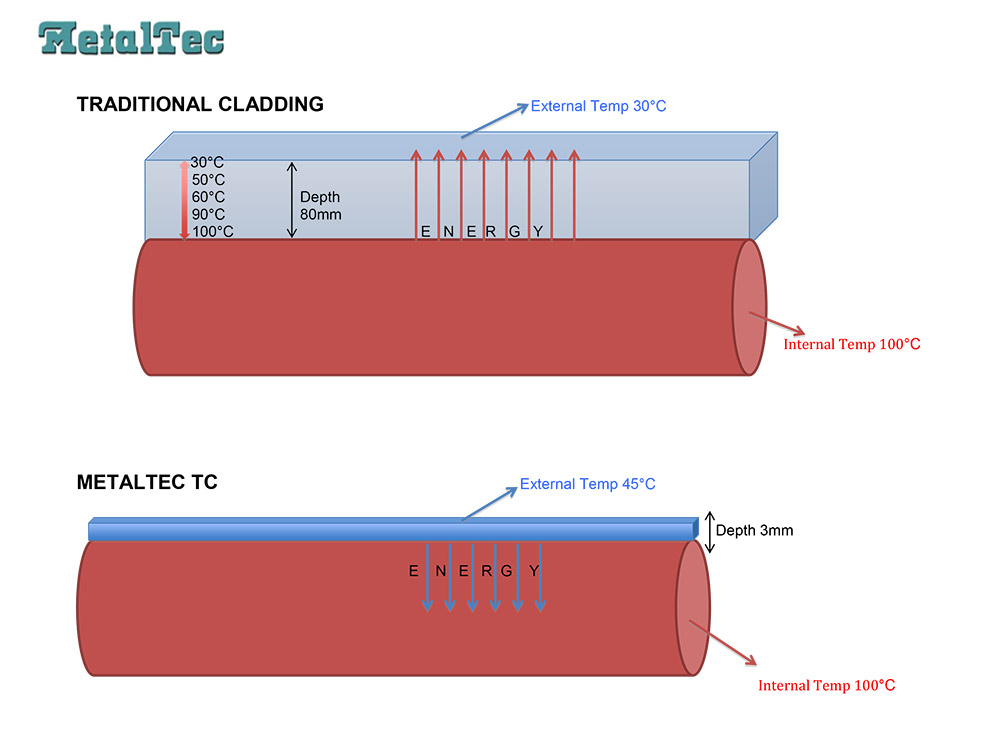

First, a little background: Rockwool or glasswool was used for the first time in the early 1950’s. At that time the industrial world was booming and saving energy was rarely considered due to the relatively low cost of energy and labour. So cladding was primarily developed to protect personnel from contact burns with steam pipes.

[ click to enlarge ]

The energy that comes out of the pipe is dissipated slowly in the rock wool and thus in the air throughout its mass. This explains why the temperature of the aluminum hull is close to 60°C. This simple fact shows that energy is still being lost to heat the aluminum. It can only comes from the pipe, which despite the cladding continues to dissipate heat demonstrating its low capacity to conserve energy. So there are big energy losses occuring under the cladding. Additionally, the more humidity is present in the air (and therefore in the rock wool), the higher your energy losses will be.

The calculated loss of cladding’s insulation capacity is directly proportional to the rate of humidity in the air. For example: with 80% humidity in the air, (which is common in Mauritius), the coefficient of thermal conductivity loss is 80% of its capacity to provide thermal insulation.

In comparison, Métaltec TC, adheres so well against the pipe surface, that it does not allow a large volume of energy to escape. The rule of three, based on a principle of simple thermodynamics, measures the amount of energy savings achieved by measuring the coating surface temperature (and thus the pipe): With a temperature of 100°C at the surface of the bare pipe, and a measured temperature of 50 ° C at the surface of the subsequently coated MetalTec TC pipe, an energy retention of 50/100 = 50% is shown because 50% of the energy has remained at the pipe surface.

Rockwool manufacturers will show a maximum energy saving produced by Rockwool of 10-15%. Métaltec TC provides up to 60-70% in energy savings. Many tests have been undertaken (results available) and given proven results in food, textile, chemical and thermal power plants. The future of thermal insulation is now within your reach!

By applying 0.75 to 1 mm of MetalTec TC on the internal walls of a building or in the box

surrounding equipment that generates noise, there is a significant reduction in the volume of sound.

By applying 0.75 to 1 mm of MetalTec TC on the internal walls of a building or in the box

surrounding equipment that generates noise, there is a significant reduction in the volume of sound.

Ice vessels coated with TC in harmony Gold mines South Africa.

Great energy savings up to 10 millions AUD/year

We have just mentioned some of the many different uses of MetalTec TC. However, our customers are always thinking about additional applications, whether in construction, industry or leisure. Do not hesitate to contact us if you have any queries.

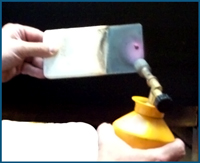

Here is a metal sample coated on 50% of its surface with

2 mm of MetalTec TC. After applying a flame on the unprotected part for 5 minutes, an infrared thermometer reads 400° C

while the coated part remains between 30 and 40° C and stays safe to touch...